The Construction of Space Shuttle Launch Complex 39-B

A very personal and technical written and photographic history, by James MacLaren.

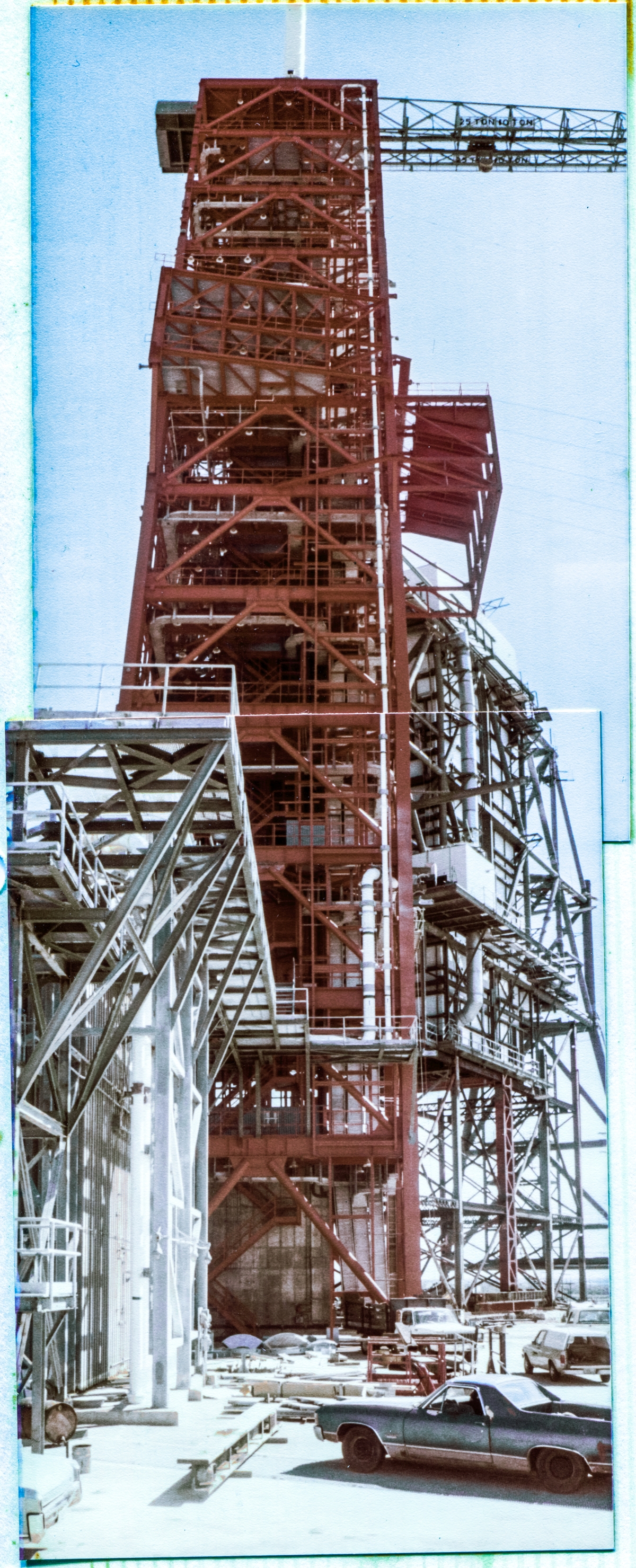

Page 14: Fixed Service Structure.

| Pad B Stories - Table of Contents |

This is a pretty unusual look at the FSS, still retaining its original Apollo-era LUT red paint job, viewed from an unusual location north of it, over behind what we called "the 9099 Building," which is all of the gray stuff over on the left side of the frame.

The 9099 Building was quite the contraption, all by itself.

Quite ugly, too.

Located as it was, butt up against the MLP, far too close for comfort to what comes out of the nozzles of the SSME's and the SRB's, it was built like a battleship, and could probably have withstood a near-direct hit from an atomic bomb. It was quite sturdy, and employed a lot of heavy tube steel members in addition to the more usual wide-flange beams, structural pipes, and angle-iron that you would encounter elsewhere, and all of this only added to it differentness, and perhaps its ugliness, too.

And, strictly speaking, it was only a small part of all that gray snarl of stuff you're seeing here in the lower half of the image, over on the left side, but everybody, at all times, always referred to the whole thing as the 9099 Building. Nobody I came in contact with ever called any of it the "Lox Tower." Nobody ever called any of it the "ECS Tower." Nobody ever called any of it "PTCR Service." Nobody every called any of it "Elevator Number 2" and, impossibly, it was not until forty literal years later, while doing research for these photo-essays, that I even so much as suspected the existence of an elevator over in that snarl of junk in the first place. Everybody called it the 9099 Building, and that's what we're going to be doing here, too.

Here's a layout of the whole area, labeled so as you can see where the main players in this area are located, but there's quotes around "9099 Building" for a reason, and that reason is that almost none of what I have shaded in green is actually the 9099 Building.

But that's what we always called the whole thing anyway, ok?

"9099" is an Apollo-era electrical systems "Reference Designation Number" and the 9099 Building, along with a significant amount of all the other Pad Deck structures in this area, is a holdover from the Apollo Program. Original unmodified equipment from the 1960's, built for Apollo, to get Niel and everybody else to the MOON and back, that was reused for the Space Shuttle Program. We will be getting into the details of this stuff later on. We will be getting extraordinarily deep into the details of this stuff later on, but not right now, ok? Maybe make a mental note of it. Because, it's coming. It's coming on Page 41, and when it gets here... phew! Don't say I didn't warn you, ok?

From a strictly-visual-appearances point of view, the 9099 Building had none of the otherworldly sci-fi ambiance that attached to the FSS or the RSS or any of the rest of the Pad.

It was just a big dumpy, ugly... thing, with a whole lot of ungainly-looking platforms and bracing sprinkled around with heavy-gauge corrugated metal siding underneath it in places, sitting over there off to the side, and although you could never accuse it of being small, it was nonetheless dwarfed into insignificance by the FSS which loomed far above it and which was much more arresting visually.

A lot of Cryo, Environmental Control, and Electrical systems went through what we called the 9099 Building, which fed no end of stuff into the MLP, the FSS, and (going right on through the FSS and out the other side), the RSS, and in all the years I tromped around, and on, the goddamned thing, I successfully managed to learn almost nothing about any of it. I could have done better. I could have done much better. But alas, I did not, and I regret not having done better to this day.

As I just mentioned, it was an already-in-place, already-built, Cryo, Environmental Control System, and Electrical (which is in fact what the "9099 Interface" actually is) installation, and as such we, as structural people, had very little to do with it. It was already there, we didn't interact with it, and my experience base with it was stunted accordingly. We hung a few flip-up access platforms off the MLP side of it, but even those were dumpy and ugly, and... I dunno. The place never once exerted any of the draw that almost everything else out on the pad urged me toward it with.

Of all the stuff on that launch pad that I wish I could go back and revisit, the 9099 Building is one of the places I'd like to return to the most. I was an idiot to not have delved into its inner workings when I had the opportunity to.

Sigh.

Ok, back to the picture.

Lotta cool stuff going on with this picture.

Another one of my favorites, in fact.

There's such an overwhelming mess of chaotically-complex stuff going on here that I'm gonna need to be careful about jumping around too much, describing what you're seeing here.

Let's start simple, and hope for the best, and I suppose I can start off with the steel beam that's laying on a couple of pieces of 4x4 cribbing, down on the ground in front of somebody's car.

Here it is here, and I've cropped most of the top off of the image, just to keep things a little more centered-up.

Take a look at the flanges on that beam. Take note of the thickness of those flanges. They're not as thick as the 4x4's the the beam is sitting on, but they're thinking about it.

Let's do a little eyeball-guesstimating with it, just for fun.

Our first guess is that the beam itself is a W14. W14's are very standard shapes, especially for heavy stuff. Skyscrapers. Big bridges. Stuff like that. So, just based on that alone, coupled with the appearance of the thing, we're going with that.

Now. Flanges.

4x4's are actually 3½x3½" so we then use 3½ as our starting point for estimating flange thickness on this piece of steel, and my eyes tell me it's about 2½" thick, and we'll toss in 1½" for web thickness, and let's go have a look at the steel book and see what that spits out for weight... and my eyeballing yields up a structural shape that matches things pretty closely (for good or for bad), and we see that a W14 x 342 looks to be that best match, so what we're looking at sitting here all so innocent and nondescriptly on the pad deck weighs a very substantial 342 pounds per running foot. And then we'll just guess some more that it's 10 feet long, and we now see that we're looking at over three thousand pounds of iron in just that one piece alone, sitting there on the cribbing, minding its own business.

And then we cast our gaze around a little wider, and look at all that other stuff that's out there all over the place, and maybe we can start to appreciate, maybe only the tiniest little bit, but still... and that's one hell of an installation they're putting together up on top of that concrete, eh?

Yeah. That it is.

And since we're having so much fun with this one single piece of iron, why stop now?

We do not know where it came from, nor where it's going.

But we can surmise.

And the surmise that makes the most sense to me is that it's part of the stuff Wilhoit used to make the falsework out of.

The stuff that's holding up the whole RSS before the RSS is ready to hold itself up.

Which had better be some pretty strong stuff, and a W14 x 342 qualifies nicely as fairly strong stuff.

So ok.

So to begin with, my knowledge of Cecil Wilhoit, founder, owner, and beating heart of Wilhoit Steel Erectors, is woefully inadequate. I deeply wish it were other, it is not.

On my second day at the Pad, everybody was pretty distraught over the the fact that somebody named Cecil Wilhoit had died unexpectedly, and despite the fact that the Wilhoit field trailer was right next to the one I was sitting in, the profound depth of my ignorance at that moment in time completely blocked me from having any idea who that person might have been, or what that might have meant. All I will ever have will be memories of sitting in the chair at my desk next to the phone, not knowing ANYthing about where I was or what was going on there, or who the main players were, or anything else about any of it, with people entering the trailer obviously distraught about the sudden death of a man I would never get to meet, going into the far end of the trailer to Dick Walls' office to talk to him about it, and RW himself being unable to properly convey any of the real meaning, the ramifications, of what had just happened so unexpectedly.

I therefore did not know Cecil Wilhoit from the man in the moon, but as time went by, I managed to pick up a few scraps of information, here and there.

Cecil Wilhoit was, apparently, originally from somewhere in South Carolina, and was one of the best you could ever hope to find, in not only what we were doing, but also in this sort of work as practiced over water, with barges and such all, doing bridges, or whatever.

Cecil had that savvy that only the very best had, and that kinda makes sense, 'cause he won not only this bid to erect the RSS at Pad B, but he also won the bid to erect the RSS at Pad A, and that was with a completely different prime contractor.

So Wilhoit the man, and Wilhoit the company, very obviously knew their shit.

I've got a feeling I would have liked the company of Cecil Wilhoit. Probably a difficult sonofabitch. Probably wasted few words. On anything. Or anybody.

My kinda people.

But I'll never know.

I came this close... but I missed.

Anyway, my guess is that this piece of iron that we're talking about here, is part of what the falsework was assembled from, and I'm further guessing that all of it came from a bridge demo job somewhere (the funny dual-member, cross-hatched with a lot of short, zigzagging, closely-spaced flat-bar diagonal bracing, appearance of so much of it is what's putting me on to this), perhaps back in South Carolina, I cannot know where, and it was grabbed for a pittance by a guy who knew his shit, who tossed it on a barge and caused it to disappear, and was very happy indeed to take it off of somebody's hands, as a favor, to keep them from having to deal with the leftovers from some damn bridge that might have been built back in the 1930's or something, and find a way to remove those leftovers and dispose of them properly without it costing 'em an arm and a leg to do so.

Cecil didn't know when that old iron would come in handy one day, but he know without a doubt that it would.

And here it is, holding up the RSS.

And that's my best guess for that.

Left of our W14, and a little bit farther away, a couple of side-by-side white ducting runs, can be seen coming up vertically, straight up out the pad deck, just inboard toward the "9099 Building" behind some heavy tube-steel framing which very nearly obscures them, running up the back of the 9099 Building, turning left up there and disappearing into the snarl of gray framing steel, only to reappear over by the FSS and then continuing to run vertically, up from there.

These are ECS Ducts (which you can see are still being modified near their upper ends behind the 9099 Building, if you look very close), which are a part of the Environmental Control System (occasionally you would see "ECLSS" stenciled on it here or there, and that stood for Environmental Control Life Support System), and that's pretty much what the whole deal was with ECS Ducts. The supply of clean filtered air to places where there were people and equipment that demanded good air, and not just any old air, at that. Clean Rooms are supposed to be kept clean, and the air was highly-conditioned for tight control of particulate matter, humidity, temperature, and "just-so" proportions of oxygen and nitrogen, and was monitored closely for anything else, such as carbon dioxide, but plenty of other stuff too, and whatever was coming out of the vents, wherever it was being supplied to, was GOOD air, and it may seem a bit over the top, but there were requirements, and not just a few of them, and you don't go leaving any of this stuff to chance, because there always exists the potential for severe punishments for getting it wrong, up to and including the loss of hundred-million dollar equipment, entire launch vehicles, and/or human lives. ECS Air was also taken elsewhere, and pretty much any place that held so much as the potential for failure as a result of being exposed to the bizarrely-reactive (it was slow, but it was relentless) beachside salt-air was furnished with ECS Air. It was all over the place.

They were playing for keeps with the ECS stuff.

This particular run stays behind the very-sturdy vertical tube-steel framing along the back side of the 9099 Building (this is actually ECS Tower steel, and we'll learn a LOT more about it when we get to Page 41), which is supporting some equally-sturdy platforming which runs toward the FSS, and this run of platforming wound up supporting (among other things) the runs of cryo piping which took LH2 and Lox to the FSS, and from there to the RSS, into the OMBUU, which delivered Liquid Hydrogen and Liquid Oxygen to the storage Dewars for the fuel-cell system that provides the Orbiter with electrical power when it was on orbit, and is why the Space Shuttle A.) did not have solar panels for electrical power production, and B.) could not stay on orbit all so very long, 'cause Lox and LH2 were both consumables, and once they were consumed, once they ran out, they were out, and if you're out of electrical power and you're still in orbit, you've got yourself a pretty serious problem, so best we come back down before any of that happens, eh?

Zoom in on the full-size photograph, look close up at the top of these white pipe/duct runs, to see how they take a left-hand bend and head horizontally farther into/above the "9099 Building" and then disappear.

From there, they head south, unseen, across and over, to a point near the FSS, where we pick them back up visually again, and from there, rising up its north side vertically, from there.

One of those (the big one which is 18" Ø) dives into the FSS just under the 120' level, and heads on over to the RSS from there. The other one (the small one which is 8" Ø) goes all the way to the top of the FSS, literally just beneath the decking at the very top, up at the 300' foot level, all the way to the Elevator Machine Room up there.

Back down on the ground, that whole zone over there, just north of the FSS, looks like it's been commandeered by the electricians, and left of the stake truck, three separate curved radius-pieces of cable tray are on the ground there, waiting their turn to get taken up to god-knows-where, and get installed on the tower someplace.

And while I'm at it here, what the hell was I standing on top of when I took this picture?.

No idea.

None at all.

But I'm up above, just a little.

I'm not standing all the way down on "ground" level.

I dunno. Me, being me, I can easily imagine that I just climbed up on something. A truck? Somebody's car, even. I have no recall of the actual taking of this photograph. But the perspective of the image is not to be denied. I was up, just a little bit, on something.

And my goodness, but isn't that FSS a lovely shade of red? This is the original Apollo Program color-scheme, which they retained when they cut the LUT on Mobile Launcher Three into pieces, (40-foot sections) and welded the pieces back together to create the FSS out on Pad B, which is what you're seeing here.

Didn't last, though.

During my tenure between steel jobs with Sheffield Steel, and Ivey's Steel Erectors (those photographs, and the stories that go with them, will be coming, but not until I finish all of the images from my Sheffield Steel days first), they came along and sandblasted the whole tower and repainted everything gray.

And periodically, from then on, every few years, they'd shut the whole place down temporarily, do all of their launch operations off of the other pad (whichever one was not being sandblasted and painted at the time) and then come back and do it once again.

When I was with Ivey, we endured much at the hands of the corrosion control "experts," and significant sums of money were squandered, and significant risks to personal safety were endured, attempting to satisfy "coating" requirements that were ostensibly invoked to ensure the towers did not rust to pieces in the surprisingly-corrosive beachside salt-air, but were actually just the small-minded directives of a couple of petty martinets who sought to exercise absurd levels of personal power, for the mere sake (and I'm not fully convinced that there was not a sizable portion of sheer malicious pleasure in there too) of being able to do so, and to bully people around in so doing. We will be hearing much more about the paint spec that was invoked at that time, KSC-STD-C-0001, but for now, it's more than enough to know that there exists a dark underside to some of what we were doing, and not everybody was a proper team player, and some of them were out to simply hurt you for the sheer devil of it, and I learned much about the ways of people and organizations at the hands of some of the more nasty ones. We will be hearing much more about different aspects of the dark underside of things too, expressed differently, in different places, by different people, and different organizations. Some of it got pretty ugly. Sigh.

This is also a nice angle for getting a proper look at the Emergency Egress Slidewire Platform up there on the back of the FSS at the 200' elevation, too.

Five wires, five baskets, but in this photograph, you only see the framing and the slidewires themselves, and the baskets did not show up for a long time (years), and looked nothing at all like they look in the rendering you see here on Drawing A-2, which was created far before any of the particulars of the baskets, as-furnished, had been in any way finalized, and which rendering has a nearly quaint aspect to it, somehow.

They increased that number to seven, later on in things. At some point they decided that five two-person baskets was not enough, so ok. So seven it shall be, from henceforth.

And so it was done. After I had already departed the Pad, so I never got any hands-on with any of that.

Just above the slidewire platform, as viewed in this image, to the left, more or less as a part of the main body of the FSS, you're getting a nice look at the support structure which helped bear the load of the Intertank Access Arm (Which does not exist in this photograph because it had yet to be furnished and installed, but which I was involved with when I returned to the Pad with Ivey Steel, and which we have a lot of really good photographs of, so stick around for that one if you can, ok?), kind of angling up and leftwards diagonally in there.

The IAA was a brute, so it needed some extra-sturdy support framing, which attached solidly to the FSS for 20 vertical feet of support framing, and 40 horizontal feet of additional support framing, and everybody always wondered just exactly why the IAA needed to be so outrageously stout, and I can only guess that it had something to do with its location, right there next to things where it could be exposed to quite a beating on launch day.

And behind the FSS, the RSS stands upon its falsework.

The back of the RSS is visible, and it is interesting to note that the pair of big HVAC Recirculation Air Ducts, which are another one of those features that give the RSS its distinctive appearance, are incomplete at this point, and there's only one of them installed, which means we were still at a fairly early stage of the game when this photograph was taken.

Zoom in on the falsework beneath the RSS somewhere around 200 percent or so, and give it a good look, now that I've mentioned "the funny dual-member, cross-hatched with a lot of short, zigzagging, closely-spaced flat-bar diagonal bracing, appearance" part of things, and maybe you'll get a little bit better of an understanding of where I'm coming from with that. There's no real engineering reason why the falsework needs to constructed out of this kind of stuff, and, knowing the business to the extent that I do, it makes a lot more sense to me when I look at it in terms of "whatever we have on hand to use" as opposed to any purpose-designed kind of thing.

Cecil Wilhoit was all about successfully bidding jobs and keeping the cash flowing, and successfully bidding jobs consists in keeping the bid amount as low as you can, and keeping the bid amount as low as you can consists in finding ways to not spend money, and using "whatever we have on hand to use" is one hell of a good way to not spend money whenever the usefulness of whatever you have on hand to use cannot be exceeded by purpose-designed-and-built alternatives. It's holding up the RSS. What the hell else do you want it to do for you? Sing you a song? Get outta here.

So that's how that works. Or at least most of the time it does. Not always. Nothing is "always."

And, speaking of that, there's no reason to believe that all of this falsework stuff came from the same place. Same demo'd bridge. Or whatever. It's a dog's breakfast down there. A very successful dog's breakfast, but a dog's breakfast nonetheless. No damn telling about it. None at all.

Here is additional background on Cecil, from Gene Hajdaj, who we've met before, and who was the RS&H Structural Field Engineer at the time, and who is one of the most sterling human beings I've ever had the pleasure of meeting in my entire life.

Verbatim.

\\\\\\\

Greetings Mr. MacLaren!

Just another true story - the Hoovermobiles

Cecil Wilhoit had a friendly personality. Well, toward me?

We often were observers of 39B critical operations together. And as we would watch, he had fun telling me stories. A typical operation was a "pick" or lift. Maybe 30 iron workers and riggers installing the next segment of the Fixed Service Structure. The stories would unfold as Cecil watched. They might suddenly stop when he observed some cryptic act in the procedure. He would personally run over to the scene and make corrections before things got out of hand. That is how Cecil "multi-tasked"?

This is one of the stories I heard while we watched:

Cecil Wilhoit was raised in a small South Carolina town during the Great Depression. Everyone was going broke all the time. One such business was a local machine shop. The owner was closing up to cut losses. And one loss that they might cut is demolition. Instead of abandoning the loser enterprise, the owner decided to "gift" the shop to Cecil. Cecil would be stuck with the "closeout" costs. However, Cecil had different ideas.

Times were bad. No one had cash. So, Cecil accepted barter. Need a replacement part machined on a lathe? Cecil would do it. And he would accept what people had. Like collard greens, chickens, eggs, whatever crop was available. One of his most popular tasks: Disconnect the steering wheel of a car and connect the front wheels to a harness and trace for horses. So that a team of horses could pull your car like a wagon. Nobody could afford gasoline.

And that is how Cecil kept the machine shop profitable: custom automobile conversions into "Hoovermobiles"!

This is what I looked like at the job trailer about the time I listened and watched "Wilhoit International"

Yes, that is the 39B RS&H field job trailer. Chris Miller had a desk and shop drawing clerk Rich Leslie had a desk.

And yes, I took trash paper and rolled it into tubes, cut to the correct length, punched holes in the ends - err work points - and bolted them together. RSS "model" was mounted on hinges so it could rotate.

I recall one of the NASA types complaining about the models - not in design services contract scope?

///////

Something else that can be seen in the photograph up at the top of this page, especially in the enlarged crop of things which show the base of the FSS as well as the Wilhoit's falsework, is an interesting triplet of Cable Trays, and they're all just a little "off" looking, not quite coming up into the FSS squarely, and it's the sort of thing that you find yourself wondering about. "Why did they put those Trays at a slight angle like that?"

And the answer turns out to be underneath the soles of your boots, down below the Pad Deck Level, and is a result of the FSS Elevator, of all bizarre things, and here's your explanation for how that works, right here on 79K10338 sheet E-24. Elevators have vastly tighter requirements for plumbness, squareness, and trueness than Cable Tray Runs ever will. Elevator Towers, be they steel, or concrete, or both, are the rigid cores of high-rise buildings, and it's no different with the FSS. You do not want your elevator or its counterweight binding, or simply jerking around side-to-side imparting unwanted forces into a system that may or may not be able to continue tolerating them, as it travels very dynamically up and down on its Guide Rails because those rails at some point diverged from the very stringent plumb, square, and true requirements for their construction. So. Elevator stuff, once they decide where they're going to locate it, has the right-of-way, second only to Primary Framing, which of course is what's holding it up, so... yeah. And then the electrical people come along with their Cable Trays, and when they bump up against something that has the right-of-way, they... move.

Also visible in this photograph is the PCR Anteroom, and you're getting a fairly good look at it here, complete with a bit of the dark opening for the entrance doorway showing, partially obscured by platform decking and random pieces of equipment, sitting off to the side of things, way over on the back of the RSS.

One thing you're not going to be getting a good look at is any structural depiction of the Anteroom, on any of the contract drawings I have been able to acquire as support documentation and illustration for these stories.

The set of drawings for Pad A, 79K04400, shows nothing at all where the anteroom clearly exists, in the photograph, but drawing V-1A in that package clearly calls it out, gives a separate drawing package number for it, as well as a contract number, contractors, and a completion date for the contract of Sep 01, 1978. So it's there, but it's not here, and I'm going to have to work with what I've got, and the only thing I've got (Note from the future: The old anteroom is shown on a couple of drawings in Drawing Package 79K24048, which showed up subsequent to the original writing of this page, but what we have here which follows, is not only adequate, but in certain ways it's actually better, and I'll let it stand, as is.) that depicts is as it existed when we built it, and when we were on the Pad, turns out to be one of the Demolition drawings from 79K14110 which covers work done prior to the installation of the gigantic Orbiter Weather Protection System which went in after I had departed the Pad, and which somehow miraculously shows things pretty much exactly as they were when I took my photographs as we built the Pad, and I've had to clean that up extensively, and remove all the demolition notes and extraneous stuff to make it properly usable, but it works. And I also doctored up the title block to flag it as being a bit of a Frankendrawing, to let people know that something's definitely up with this particular drawing, and that its unaltered incarnation is actually drawing A-11 from 79K14110, but A-11 is so laughably far out of agreement with what we built as to be unusable, so... Frankendrawing is what we need, and Frankendrawing is what we get.

So here's your anteroom, ok? Or at least the location where it sits on the framing steel down on the Main Flooring level of the RSS at elevation 135'-7".

Once again, in my 79K14110 construction (the opposite of demolition) drawings for Pad B, the original Anteroom is gone, and has been replaced by the highly-modified version of itself that we built when I was working for Ivey Steel, several years later.

So I'm going to have to manually draw it in myself, as best I can, into an altered 79K14110 drawing, A-49, and here's the original version of A-49, and here's A-49, as significantly altered by myself. Open 'em both up in separate tabs and blink back and forth between them to get a feel for how much smaller the original anteroom was, compared to its highly-modified incarnation which came later.

The Anteroom was what you had to pass through to gain entrance into the Payload Changeout Room during those times when the pad was actually being used by its owner (NASA), which, surprisingly enough, was not all the time.

If there was no vehicle on the Pad, or if there was no payload in the PCR, and during those times that maintenance and/or modifications were being performed, then they would usually leave the emergency exit doors in the PCR Air Lock wide-open, and you could just walk straight through there into the PCR without having to detour around and enter through the Anteroom.

The original Anteroom was a very cramped affair, with barely enough room for a desk and the person who sat behind it, who was there to check your badge and verify you had proper authorization to proceed further into the Payload Changeout Room.

Once given the go-ahead, you would turn and hit the button to open the Air Shower, which was only slightly-larger than the size of a telephone booth. It was small, and had doors on opposite sides, and you would pass through it, only one person at a time, but to do so, once inside, you had to wait for a bit. The doors would automatically latch and seal, and you would be hit by strong jets of ECS-conditioned air, from above and below, as a measure to knock off any loose dirt or debris that may have been clinging to you, to eliminate contamination from the clean room environment you were about to enter. Then the air would shut off, and you'd hear the clicks of the doors as they released, and you could then proceed out the side of the Air Shower opposite the side which you entered, and once beyond that door, you were now inside the PCR Air Lock, which was larger but not particularly large, where you could sit down on one of the benches that lined either wall, slip on the little shoe-cover booties which were available there, and which covered your footwear as another measure to maintain cleanliness inside the PCR itself. From that point, you tore open the sealed plastic bag which contained your bunny suit which you had requisitioned earlier, down in the bowels of the Pad in the Pad Terminal Connection Room, stepped into the bunny suit, and then and only then, passed through the doors on the side of the airlock that abutted the PCR, and actually entered the Payload Changeout Room itself.

In our photograph at the top of this page, we're seeing the original configuration of the Anteroom, with which I am familiar, but it only lasted a few years, and never made it to the point by which time Pad B had become operational and was supporting launches. It was completely and extensively reworked, enlarging it greatly by extending it all along the back side of the PCR and they also added a large Storage Room back there between Lines 6 and 7, and the whole place is vastly different than the place I worked at, ok? And although the old Anteroom did not make it to "operational" status at B Pad, it was used in its original configuration at A Pad for a pretty good while, and I passed through it my share of times over there before they tore it apart and put it all back together again, much enlarged. As with so much else, we'll be seeing more about the Anteroom later on, with more photographs and stories.

There's plenty more here, too, but isn't that enough for now?

We'll hit the other stuff somewhere else, ok?

Return to 16streets.comACRONYMS LOOK-UP PAGEContact Email Link |